BONDING GUIDE

INTRODUCTION

Greenwire provide a range of products for effective bonding of electrically conductive components to the Lightning Protection System.

EQUIPOTENTIAL BONDING

An important aspect of a Lightning Protection System (LPS) is that electrically continuous parts of a structure must be bonded into the Lightning Protection network.

The purpose of this bonding is to ensure that, in the event of a lightning discharge, any sparking or flashover of the lightning current to conductive parts of the structure, for example water pipes, cables etc is avoided.

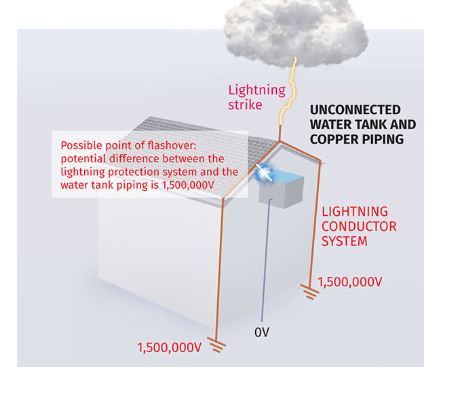

This is illustrated in the diagram to the right . . .

EXPLANATION

During a lightning strike the lightning conductor system could reach 1,500,000 volts with respect to earth, whilst the copper piping connected to the water tank is at 0 volts to earth.

The impedance of the lightning conductor system will determine the “potential difference” between the two systems with respect to earth, as well as the distance that the water tank is away from the lightning conductor. If the potential difference is large enough, it may cause breakdown of the insulation effects of the roof and air, leading to a spark flashing over to the water tank.

Equipotential bonding in this respect, is essentially the connection of conductive metallic parts of the structure such that in the event of a lightning discharge, no potential differences exist between the lightning conductor system and the “other conductive low impedance pathways”.

Materials that can provide a fortuitous low impedance pathway and may require bonding into the lightning protection system are such as:

- Cable screens

- Metallic pipework

- Metallic handrails, stairways, screens

- Structural steelwork

- Reinforcing bar

- Ductwork etc

- Supporting structures for curtain wall systems

- Metallic cladding systems for buildings

The risk of flashover can increase in the presence of:

Incorrect routeing of conductors

High impedance lightning protection system – due to the installation of poorly designed components, or inferior/corrosion prone materials

FROM BS:EN 62305 . . .

Some implications for bonding

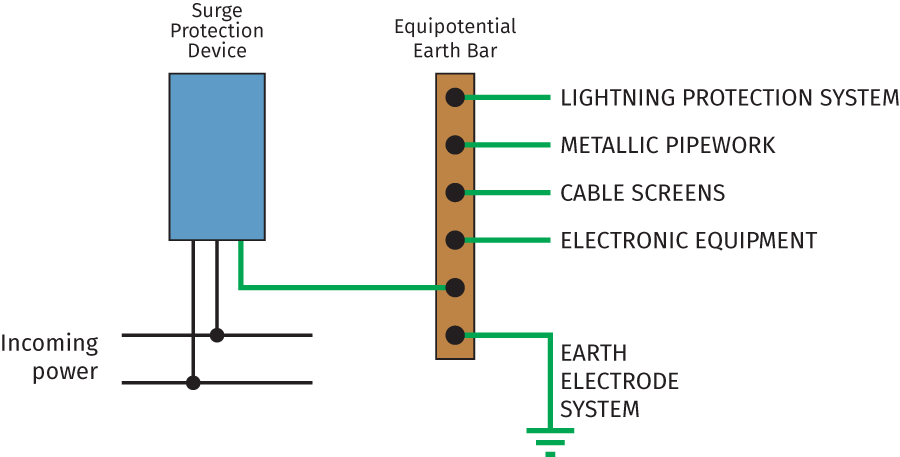

In a well-designed system, all metallic/conductive services, such as water and gas pipes, power, telecommunications and data cables would enter the building in the same locality and be connected to a single earth bonding bar. Which, in turn, would be connected to the earth termination network, as well as the conductive parts of the building.

However, life isn’t that simple and services enter and exit at different places. It is recommended that services are bonded at their point of entry to/exit from the building.

Equipotential bonding can be achieved through:

Direct Connection

Utilising earth bonds, earth clamps and bonding conductors which link the various metallic services and parts of the structure to Earth Bars.

The standard outlines the minimum cross-sectional area of conductors to be used in these applications.

Earth Bars act as collection points for the various lightning protection and earth continuity bonds and their subsequent connection to the earth termination. Each Earth Bar would be connected to earth.

Surge Protection Devices (SPDs)

It is recommended that the live cores of power, telecommunication and data cables are equipotentially bonded through using appropriately rated Surge Protective Devices.

A simplified illustration of equipotential bonding using SPDs is demonstrated here . . .

Guidance for the selection of equipotential bonding or lightning current SPDs can be found HERE.

Isolating Spark Gaps (ISGs)

Are suitable for use where the direct connection of an external Lightning Protection System and other metallic parts or earthing system is not allowed due to operating reasons. For example, earthing systems for heavy current and telecommunications systems or bridging isolated flanges on pipe connections.

When a difference in potential occurs between these parts, the Isolating Spark Gap (ISG) will provide a temporary conductive connection to earth, thus reducing dangerous potential difference issues (a simple explanation of potential difference).